Water-based wood paint has the advantages of being green, environmentally friendly, safe, and non-yellowing, and is widely used in many industries. But it also has problems such as poor fullness and poor stain resistance. Silane coupling agent (KH560) is a type of organic silicon compound. Adding it to paint can increase the bonding strength between substances and improve the water resistance, weather resistance and other properties of the paint. Silicone resin is a type of polyorganosiloxane that has a unique network structure and excellent moisture resistance, waterproofing and rust resistance, but poor solvent resistance. This article conducts optimization experiments by adding additive KH560 and silicone resin to collaboratively modify water-based coatings, in an attempt to improve the mechanical properties and optical properties of water-based coatings.

1 Experimental Part

1.1 Experimental materials

All reagents in the current experiment are of unprocessed analytical grade. The modifier is KH560 and silicone resin, the substrate specification is (100mm*100mm*5mm), and the surface has been coated with primer.

1.2 Coating preparation

First, sand the base material with sandpaper and apply primer. The added amounts of KH560 and silicone resin are added to the water-based wood coating according to the pre-designed amount. Stir evenly with a glass rod, and then evenly apply the mixed coating on the wooden substrate (100mm*l00mm*5mm) that has been flattened by primer. ), the coating thickness is about 60pm. Then put it into the oven, set the drying oven temperature to 40°C, and set the drying time to 15-30 minutes.

1.3 Testing and Characterization

Measure the adhesion with a coating film adhesion tester according to GB/T1720-89. Measure hardness according to GB6739-86. Glossiness is tested according to BGD512-60 gloss meter. 2.2 Effect of silicone resin on the mechanical properties of water-based wood coatings

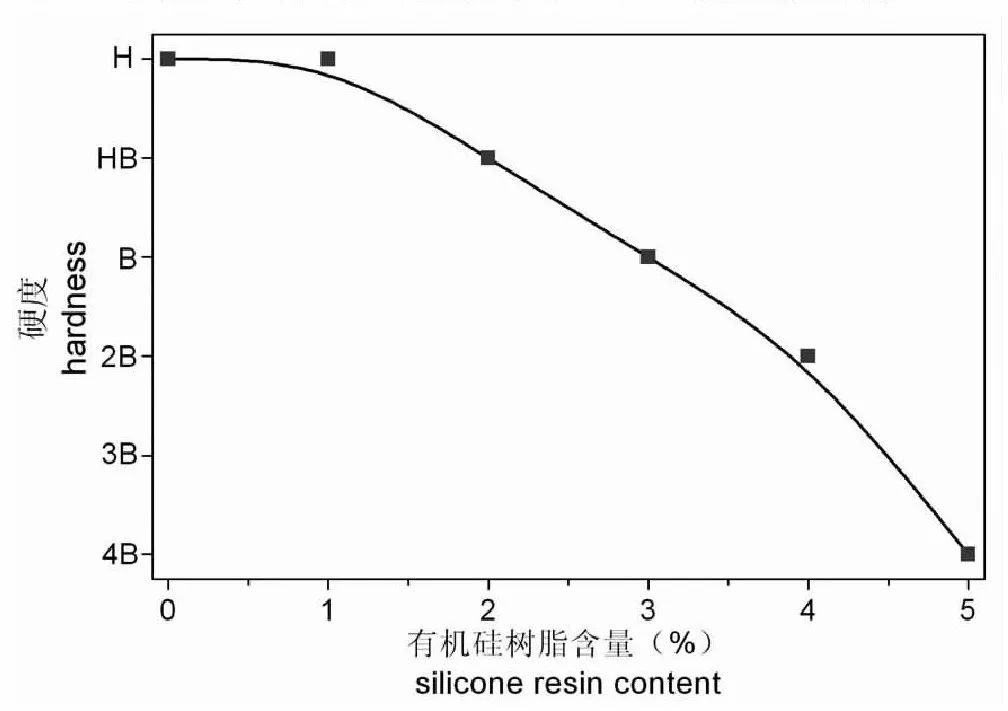

In order to study the key role of silicone resin, based on the orthogonal experiment, the following series of experiments were conducted: the content of KH560 was fixed at 2.0%, the drying time was fixed at 15min, and the content of silicone resin was changed to 0. , 1.0%, 2.0%, 3.0%, 4.0%, 5.0%. Silicone resin content was found to have a role in the hardness of waterborne wood coatings. Figure 1 shows the effect of silicone resin content on the hardness properties of water-based coatings. When the silicone resin content increases from 0 to 1%, the hardness of the water-based wood coating always remains at H. When the silicone resin content is continued to be increased to 5%, the coating hardness continues to decrease, reaching 4B. At this time, the hardness of the paint film is already very low. This is because the content of silicone resin is too high, and the binding force of water-based coatings is severely reduced, causing the paint film to become soft.

Figure 1 The relationship between the content of silicone resin and the hardness of water-based wood coatings

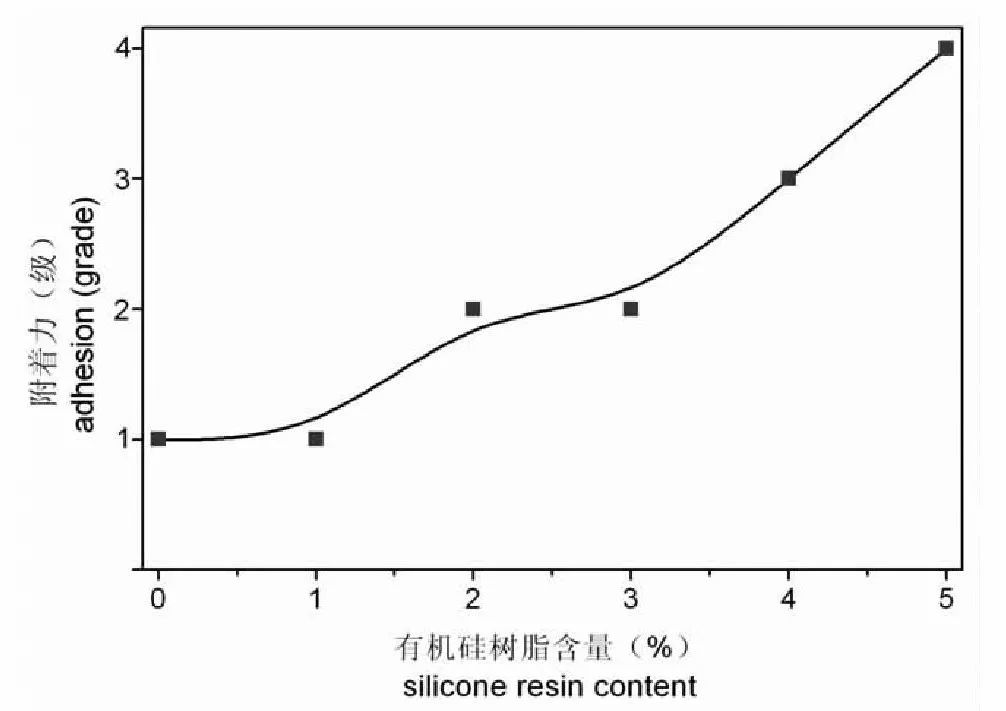

Figure 2 The relationship between the content of silicone resin and the adhesion of water-based wood coatings

It can be seen from Figure 2 that as the content of silicone resin increases, the adhesion basically shows a downward trend. When the content of silicone resin is less than 2%, the adhesion performance is better. The reason is that the silicone resin reacts with the water-based coating, but it has not yet had a significant impact on the adhesion. At this time, it mainly relies on the adhesion of the KH560-modified water-based coating. Continuing to increase the content of silicone resin will cause changes in the proportion of chemical components inside the water-based coating. This change in proportion will reduce the adhesion of the coating. Therefore, as the content of silicone resin increases, the adhesion will become worse.

2.3 Effect of silicone resin on the gloss of water-based wood coatings

Figure 3 The relationship between the content of silicone resin and the gloss of water-based wood coatings

The effect of silicone resin coating content on gloss is shown in Figure 3. As can be seen from Figure 3, the glossiness of the water-based wood coating changes very little as the silicone resin content increases, but compared with the empty plate sample, the glossiness decreases slightly. This is because the water-based paint itself has high gloss, the silicone resin content increases, and the volume concentration increases during the coating process, forming a slightly rough surface, thereby reducing the gloss of the water-based wood paint.

3 Conclusion

Orthogonal test results show that the silicone resin content determines the mechanical properties of water-based wood machine paint. Experimental description: Dry in an oven at 40°C for 20 minutes, the KH560 content is fixed at 2%, and the silicone resin content increases from 0 to 1%, the hardness of the water-based wood coating is H, and the adhesion does not change much, both are level 1 . When the silicone resin content is continued to be increased to 5%, the coating hardness drops to 4B and the adhesion drops to level 4. Glossiness shows that the silicone resin content has no significant effect on the glossiness of the water-based wood coating, and the overall glossiness value is between 80% and 85%.

ord-wrap: break-word;”> 2.3 Effect of silicone resin on the gloss of water-based wood coatings

Figure 3 The relationship between the content of silicone resin and the gloss of water-based wood coatings

The effect of silicone resin coating content on gloss is shown in Figure 3. As can be seen from Figure 3, the glossiness of the water-based wood coating changes very little as the silicone resin content increases, but compared with the empty plate sample, the glossiness decreases slightly. This is because the water-based paint itself has high gloss, the silicone resin content increases, and the volume concentration increases during the coating process, forming a slightly rough surface, thereby reducing the gloss of the water-based wood paint.

3 Conclusion

Orthogonal test results show that the silicone resin content determines the mechanical properties of water-based wood machine paint. Experimental description: Dry in an oven at 40°C for 20 minutes, the KH560 content is fixed at 2%, and the silicone resin content increases from 0 to 1%, the hardness of the water-based wood coating is H, and the adhesion does not change much, both are level 1 . When the silicone resin content is continued to be increased to 5%, the coating hardness drops to 4B and the adhesion drops to level 4. Glossiness shows that the silicone resin content has no significant effect on the glossiness of the water-based wood coating, and the overall glossiness value is between 80% and 85%.